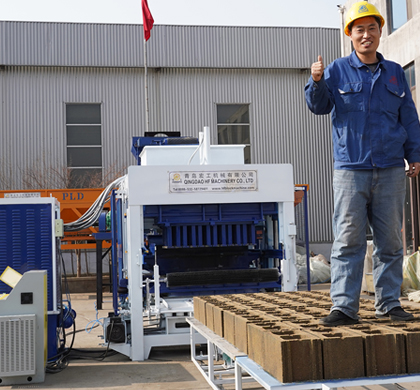

1,Introduction: Identifying The Quality of Block Making Machine Equipment

The quality of a block making machine is determined by the number of blocks it can produce in an hour.

A high quality block making machine will be able to produce a large number of blocks in an hour. A low quality block making

machine might take much longer to produce a smaller amount of blocks.

.jpg)

2,How to identify the quality of a block making machine?

The quality of a block making machine equipment can be determined by the following factors:

1. The durability and efficiency of the machine

2. The ease of operation

3. The reliability of the parts and components

4. The materials used in production

.jpg)

3,How to evaluate machines by their specifications.

Evaluating machines by their specifications is a way to assess their potential. It can be done by looking at different aspects

of the machine and its components.

There are many ways that you can evaluate a machine. Some people prefer to look at the specifications sheet, while others

may want to take a look at the reviews of other customers. You will need to find what works best for you and go from there.

.jpg)

4,How to compare machines based on their performance metrics?

To compare machines based on their performance metrics, you need to be able to measure the performance of each machine.

This can be done using a common metric called "mean time between failures". This is the average amount of time between failures

of a machine.

The metric that is used by most people is "mean time to failure" or "MTTF". This measures how long a machine lasts before it fails.

.jpg)

en

en Search

Search